Advanced Print Inspect Tool¶

Warning

The AdvancedPrintInspectTool is no longer being developed and has been replaced by the LabelInspectTool.

The AdvancedPrintInspectTool performs a target/actual comparison between an input image and a training image and evaluates the differences. For this purpose, any number of inspection areas can be defined in the image. In each of these areas, a target/actual comparison is performed independently based on the structures present in this area in the training image. The position of the structure in the input image, e.g. a letter, is determined using PMAlign or CNLSearch. Once the structure has been found, an evaluation can be performed using PatInspect followed by a blob. This tool is usually used to check printings, hence the name.

Records¶

Current.InputImage: The current input image. Also displays the search regions. Here you can set the search region of an inspection where a user-defined search range is used

Current.TrainImage: The training image on which the training regions for the can be changed.

LastRun.InputImage: The last checked input image. Visualization of search regions, errors, etc.. Errors are always displayed in red. A red search region means that the inspection was not completed, for example because the structure was not found.

Tab Train¶

First, a training image must be defined. “Grab train image” takes the current input image as the training image.

In order to simplify the definition of the regions for many areas, a preselection can now be generated via a blob tool. Now the inspection areas could be defined in the tab “Inspections”.

“Open Blob Tool” opens the tool for the preselection. Here, a search area is defined as well as the threshold values and minimum sizes of the letters. The blob tool is then executed with “Find regions” and the areas identified in this way are adopted as inspection areas. For each blob found, the enclosing rectangle is determined and enlarged by the values set in “Enlarge blob region X/Y”. If more areas were found than inspections currently exist, new inspections are created.

Changes are accepted with “Train”. If the tool is not re-trained after changes, the execution is aborted with a RunError. “Train” is executed for all inspections, i.e. all CNLSearch/PMAlign tools and PatInspect tools are trained.

Tab Global run params¶

Enlarge train region X: For each inspection it can be specified whether the search region is to be calculated automatically from the training region or whether a user-defined search region is to be used. This parameter specifies by how much a training region should be enlarged in X during automatic calculation.

Enlarge train region Y: Automatic enlargement of the training region in Y

Maximum offset to train position X/Y: The position of the structure in the search area of the input image is compared with the position of the structure in the training image. If the position differs by more than the values set here, this is considered an error.

Min defect size: Minimum defect size (setting for the blob tools that evaluate the output image of the PatInspect tools).

Defect Threshold: Minimum threshold for errors

Tab Inspections¶

The list on the left side contains all inspections. The name can be freely assigned, but it makes sense that it corresponds to the structure. Use train as search region” determines whether the search region is automatically generated from the training region or is user-defined. In the toolbar, inspections can be created, deleted or moved in the list. The selected inspection is parameterized on the right:

Use cnl search as alignment: If selected, a CNLSearch tool is used to search the structure, otherwise a PMAlign tool. Which tool is more convenient depends on the structure. With “Set for all” the selection is taken over for all inspections.

CNLSearch/PMAlign: Settings for CNLSearch or PMAlign, depending on what is selected.

Evaluate alignment only: If checked, only the structure found in the search area is checked. The subsequent inspection using PatInspect and Blob is not performed.

PatInspect and Blob: Settings for inspection with PatInspect and Blob

For CNLSearch/PMAlign, PatInspect, and Blob, the following functions are available:

Edit selected: Opens the tool dialog in which the respective tool is parameterized.

Copy settings from selected: Copies the settings of the respective tool of the selected inspection to the clipboard.

Apply settings to selected tools: Applies the settings of the tool in the clipboard to the selected inspections.

Graphics Tab:¶

Alignment train images: Creates a record for the training image of the CNLSearch or PMAlign tool for each inspection.

PatInspect train images: Creates a record for the training image of the PatInspect tool for each inspection.

Blob images: Creates a record for the input image of the blob tool for each inspection.

Blob graphics: Graphics of the blob results (=blobs)

Search regions: Graphics for the search regions

Results Tab:¶

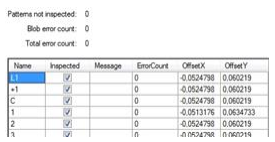

Patterns not inspected: Sum of all inspections that were not performed properly, e.g. because the structure could not be found.

Blob error count: Sum of all blobs over all inspections

Total error count: Sum of the two error categories above. This value can be used for the later evaluation

The result list contains the following columns:

Name: Name of inspection

Inspected: Has been fully inspected (otherwise a “Pattern not inspected” error).

Message: Detailed error message

ErrorCount: Number of missing parts

OffsetX, OffsetY: Deviation between target and actual position